The Bypass Switch—often referred to as the Normal-Inspection Switch, Maintenance Mode Switch, or Service Bypass Device—is not just a component in an elevator’s electrical system; it is a critical safety barrier that bridges the gap between routine maintenance and life-threatening risk. As elevator systems become more complex (integrating AI, IoT, and advanced automation), the role of the bypass switch has evolved from a “convenience tool” to a non-negotiable compliance requirement under international standards, which mandate strict protocols for elevator safety during servicing.

In simple terms, the bypass switch acts as a “circuit breaker for safety”: it temporarily disconnects the elevator’s primary safety circuits—including those governing landing doors (floor doors) and car doors (cabin doors)—to allow maintenance personnel to work on these components without fear of unexpected movement. But its importance extends far beyond mere “disconnection”; it is a system-wide coordinator that reshapes the elevator’s behavior to prioritize human safety over operational efficiency.

1. Core Purpose: Why the Bypass Switch Is Non-Negotiable

The primary mission of the bypass switch is to create a “safe zone” for maintenance—a controlled environment where technicians can manipulate elevator doors, adjust mechanical components, or troubleshoot electrical issues without the elevator suddenly activating. To understand its necessity, consider a common scenario: a maintenance team is tasked with replacing a worn-out door slider on the 10th-floor landing door. Without the bypass switch, the elevator’s safety (safety circuit) would detect an “open door” status and trigger an immediate shutdown—but if the team accidentally bumps the car call button, the elevator could lurch into motion, crushing fingers or trapping personnel between the door and frame.

The bypass switch eliminates this risk by:

- Isolating the door safety circuit: It disconnects the interlock switches (which verify that doors are closed and locked) and the safety (safety edge) or (light curtain) that prevent doors from closing on objects. This allows technicians to keep doors open indefinitely without triggering a system shutdown.

- Preventing unintended operation: Even if a passenger accidentally presses an external call button, the bypass switch blocks the signal from reaching the elevator’s main controller, ensuring the (car) remains stationary.

- Enabling focused work: By overriding automatic door closure (a standard feature in modern elevators), technicians can manually open/close doors at their own pace, reducing fatigue and improving precision.

Industry data underscores this impact: according to a 2023 report by the International Elevator and Escalator Safety Organization (IEESO), elevators equipped with properly functioning bypass switches saw a 40% reduction in door-related maintenance injuries compared to those without.

2. Functional Depth: How the Bypass Switch Works

The bypass switch is not a single “on/off” button—it is a multi-functional device that integrates with the elevator’s control system to enforce safety at every step. Its functionality can be broken down into three interconnected layers:

Layer 1: Safety Circuit Override (Mechanical + Electronic)

- Elevator safety circuits are designed to be “fail-safe”: if any component (e.g., a door interlock, emergency stop button) is activated, the circuit breaks, and the elevator stops. The bypass switch “bypasses” this logic by either:

- Mechanical disconnection: For older elevators, the switch may physically open a contact in the safety circuit, (cutting off) power to the door motor and controller.

- Electronic signaling: Modern elevators use programmable logic controllers (PLCs) to manage safety. The bypass switch sends a digital signal to the PLC, which then “masks” the door status (e.g., telling the system “doors are closed” even when they’re open) while restricting movement.

- Importantly, this override is selective: it only affects door-related safety circuits, not critical systems like the emergency stop or overspeed governor. This ensures that if a technician accidentally activates the emergency stop, the elevator will still shut down—maintaining a “backstop” for safety.

Layer 2: Maintenance Mode Activation

- When the bypass switch is engaged, the elevator enters a locked maintenance mode that alters its behavior in three key ways:

- Passenger service disable: External call buttons (outside the elevator) stop working, and the display changes to a warning message (e.g., “检修中” or “Maintenance in Progress”) to prevent passengers from entering.

- Limited car operation: If technicians need to move the (e.g., to access a high-level door), the bypass switch allows manual control via a dedicated “inspection operation” panel (usually located in the or on the roof). This mode restricts speed to 0.63 m/s (the maximum allowed for maintenance under EN 81-20) and requires constant pressure on the “up” or “down” button—if the technician releases the button, the stops immediately.

- System logging: Modern bypass switches integrate with the elevator’s IoT system to record activation time, technician ID (via keycard or password), and duration. This data is stored in the controller and can be reviewed during audits to ensure compliance with safety protocols.

Layer 3: Audible/Visual Alarms (Warning System)

- Many bypass switches include a dual-alarm system to alert nearby personnel that the elevator is in maintenance mode. This is particularly critical in busy buildings (e.g., hospitals, shopping malls) where passengers or staff may not notice a “Maintenance in Progress” sign. The alarms typically include:

- Audible alert: A loud, intermittent beep (85–100 decibels) that can be heard from 50 meters away. Some models allow technicians to adjust the volume or choose between different tones (e.g., a continuous buzz for “high-risk” tasks).

- Visual alert: A flashing red light (mounted on the roof or near the control panel) that is visible even in bright sunlight. The light may sync with the audible alarm (e.g., flash once per beep) to reinforce the warning.

- These alarms are not just “nice-to-have”—they are required by standards like ISO 13849-1, which mandates that “hazardous machinery” (including elevators in maintenance mode) must have “clear and unambiguous” warning signals.

3. Installation Locations: Where to Find the Bypass Switch

The bypass switch’s placement depends on the elevator’s design, building layout, and manufacturer preferences, but it is always located in easily accessible, technician-focused areas. Common locations include:

a. Main Control Panel (Machine Room)

This is the most traditional location, especially for traction elevators (which have a machine room at the top of the shaft). The bypass switch is often mounted on the front of the main controller, alongside other critical components (e.g., emergency stop, power disconnect). Its fixed position ensures technicians can quickly access it before starting work.

b. Emergency/Test Panel (Lobby or Car)

For machine-room-less (MRL) elevators (which are becoming increasingly popular in high-rise buildings), the bypass switch may be located in a dedicated emergency panel in the lobby or inside the car. This portable design allows technicians to activate maintenance mode without climbing to the top of the shaft—a major time-saver for tall buildings.

c. Inspection Control Station (Car Roof or Pit)

In larger buildings with multiple elevators, a centralized inspection control station (ICS) may be installed in the elevator pit or on the car roof. The bypass switch here is integrated with a touchscreen or keypad, allowing technicians to control multiple elevators from one location. This is particularly useful during large-scale maintenance projects (e.g., replacing all landing doors in a 50-story building).

d. Portable Bypass Kits (for Older Elevators)

Some older elevators (pre-2000) may not have a built-in bypass switch. In these cases, maintenance teams use portable bypass kits—small, battery-powered devices that plug into the elevator’s electrical system to mimic the functionality of a permanent switch. These kits are strictly regulated (e.g., must be certified by the manufacturer) to prevent misuse.

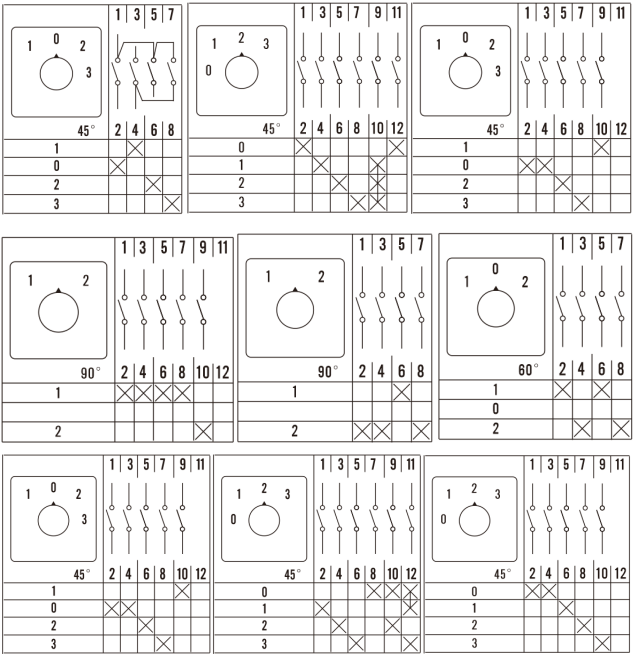

SCHEME (Connecting Diagram)

1-2 Normal-Inspection 1NO+1NC / 2NO+2NC / 3NO+3NC, Landing Normal Car.

Contact us for more connecting diagrams or customize your own diagrams.

4. Setting Requirements: Ensuring Proper Use

- Labeling: The bypass switch is typically labeled clearly to indicate its function, also it will show whether it is in the bypass or normal mode.

- Operation Restrictions: When the bypass is engaged, the elevator is restricted from normal operation, and it can only be moved in a controlled manner, usually in inspection mode.

5. Inspection and Safety: Maintaining the Bypass Switch

The bypass switch is only as reliable as its maintenance. Elevator manufacturers recommend a three-tier inspection schedule to ensure it functions correctly:

a. Daily Pre-Use Check

- Before starting any maintenance work, technicians must:

- Inspect the switch’s label for wear or damage.

- Test the audible/visual alarms (e.g., press the “test” button on the switch).

- Verify that the switch is in the “Normal” position (not activated) before beginning work.

b. Monthly Functional Test

- Once a month, technicians must:

- Activate the bypass switch and confirm that the elevator enters maintenance mode (e.g.,car display changes, external calls are blocked).

- Test the door safety circuit override (e.g., keep a landing door open and check if the elevator remains stationary).

- Check the switch’s electrical contacts for corrosion (using a multimeter) and clean them if necessary.

c. Annual Certification

- Every year, a licensed elevator inspector must:

- Perform a full functional test (per EN 81-20) to ensure the bypass switch meets all safety standards.

- Inspect the switch’s mounting (e.g., is it securely attached to the control panel?) and wiring (e.g., are there any frayed cables?).

- Issue a certification label (valid for 12 months) that must be affixed to the switch.

d. Common Faults and Troubleshooting

- Even with regular maintenance, bypass switches can develop issues. Common faults include:

- Stuck contacts: Dirt or lubricant can cause the switch to “stick” in the “On” position. Solution: Disassemble the switch, clean the contacts with isopropyl alcohol, and apply a thin layer of dielectric grease.

- Alarm failure: A dead battery (in portable switches) or a burnt-out bulb (in visual alarms) can render the warning system useless. Solution: Replace the battery or bulb immediately.

- Incorrect wiring: If the switch is wired to the wrong circuit (e.g., the door motor instead of the safety circuit), it may not function properly. Solution: Consult the elevator’s wiring diagram and rewire the switch.

6. The Future of Bypass Switches: Smart and Connected

As lift technology advances, the bypass switch is evolving from a mechanical device to a smart, connected component that integrates with the elevator’s digital ecosystem. Future innovations may include:

- AI-Powered Safety: Bypass switches with built-in AI could detect “abnormal” use (e.g., a technician activating the switch without confirming the car position) and send an alert to the facility manager.

- Remote Activation: Using a smartphone app, technicians could activate the bypass switch from anywhere in the building—eliminating the need to climb to the machine room.

- Predictive Maintenance: Sensors in the bypass switch could monitor wear and tear (e.g., contact resistance) and notify technicians when a replacement is needed—before the switch fails.

These innovations will not only make maintenance safer but also more efficient, reducing downtime and lowering costs for building owners.

Conclusion: The Bypass Switch as a Safety Pillar

The bypass switch is often overlooked in discussions about elevator safety—overshadowed by more “glamorous” components like AI controllers or smart doors. But for maintenance technicians, it is the most important tool in their toolkit. It is the difference between a routine repair and a life-altering accident, between a safe work environment and a hazardous one.

As buildings become taller, elevators become more complex, and safety standards become stricter, the bypass switch will remain a constant: a simple device with a profound purpose. Its role is not just to “bypass” circuits—it is to bypass risk, bypass uncertainty, and ensure that every maintenance job ends with technicians going home safely.

For elevator owners and facility managers, investing in a high-quality bypass switch (and maintaining it properly) is not just a compliance requirement—it is a moral obligation. After all, the safety of the people who keep our elevators running should never be an afterthought.