Introduction

Dahlander Motor Switches are essential for controlling dual-speed, pole-changing motors in industrial machinery, HVAC systems, and conveyor belts. Choosing the correct switch ensures efficiency, safety, and longevity. In this guide, we’ll break down key selection criteria, supported by technical diagrams and expert resources.

1. Understanding Dahlander Motor Switches

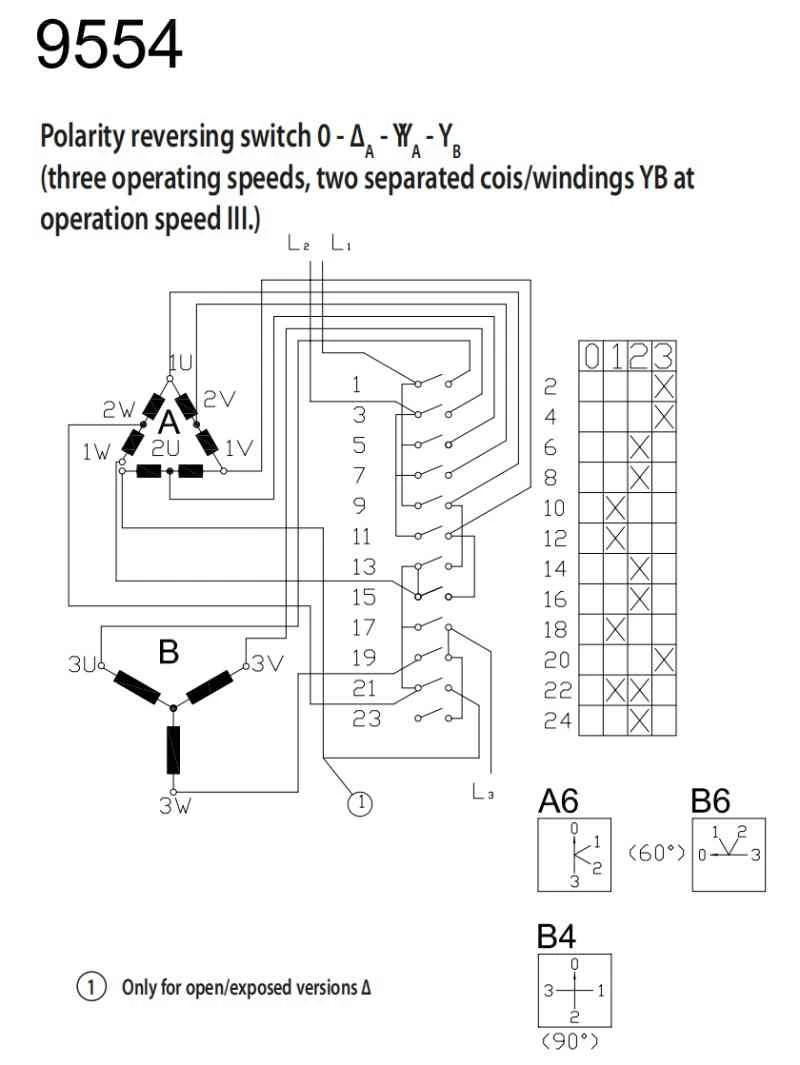

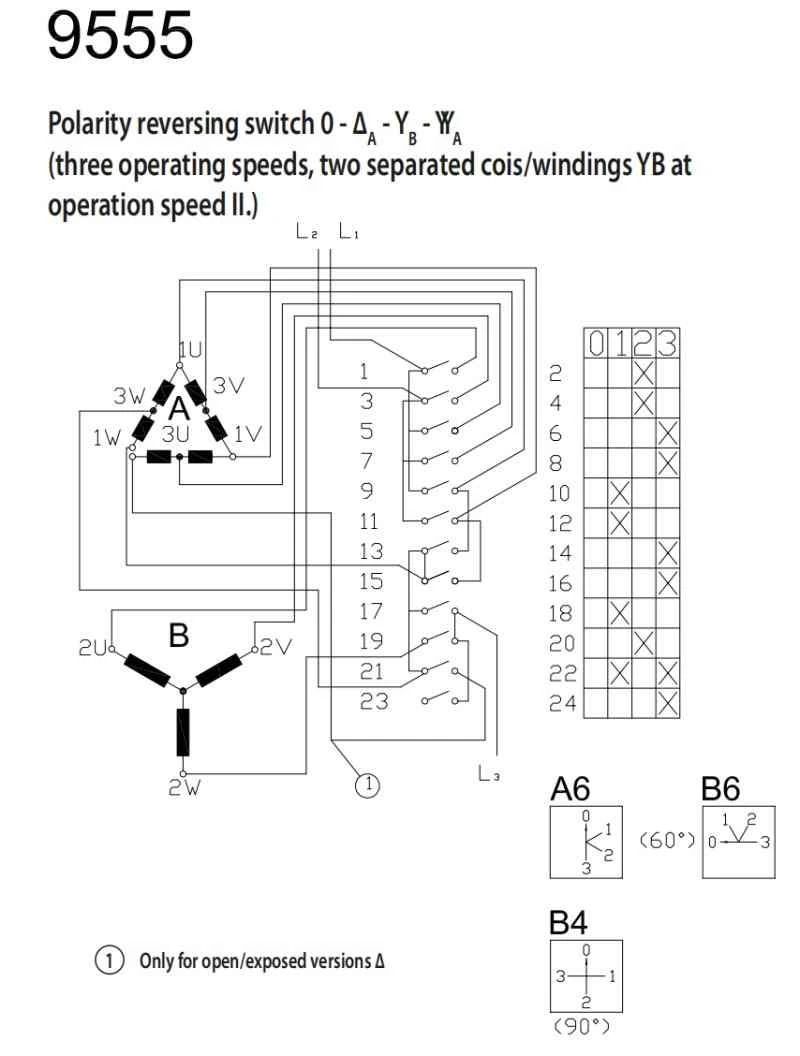

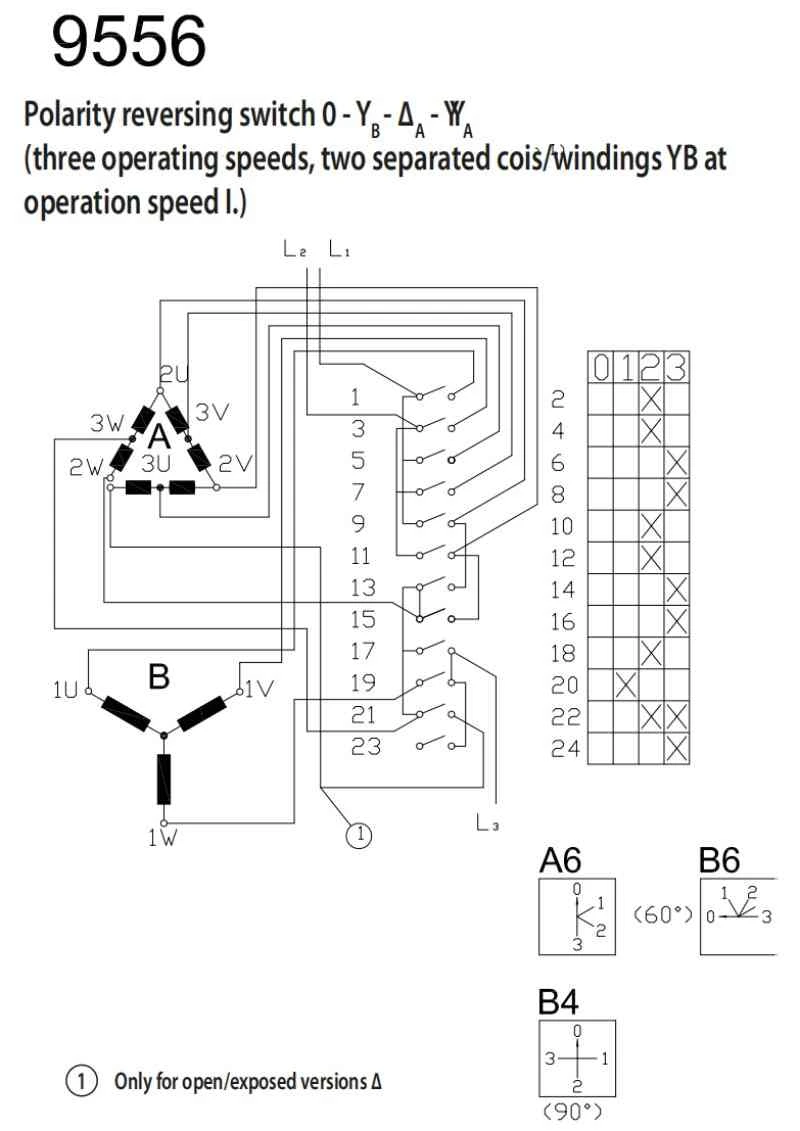

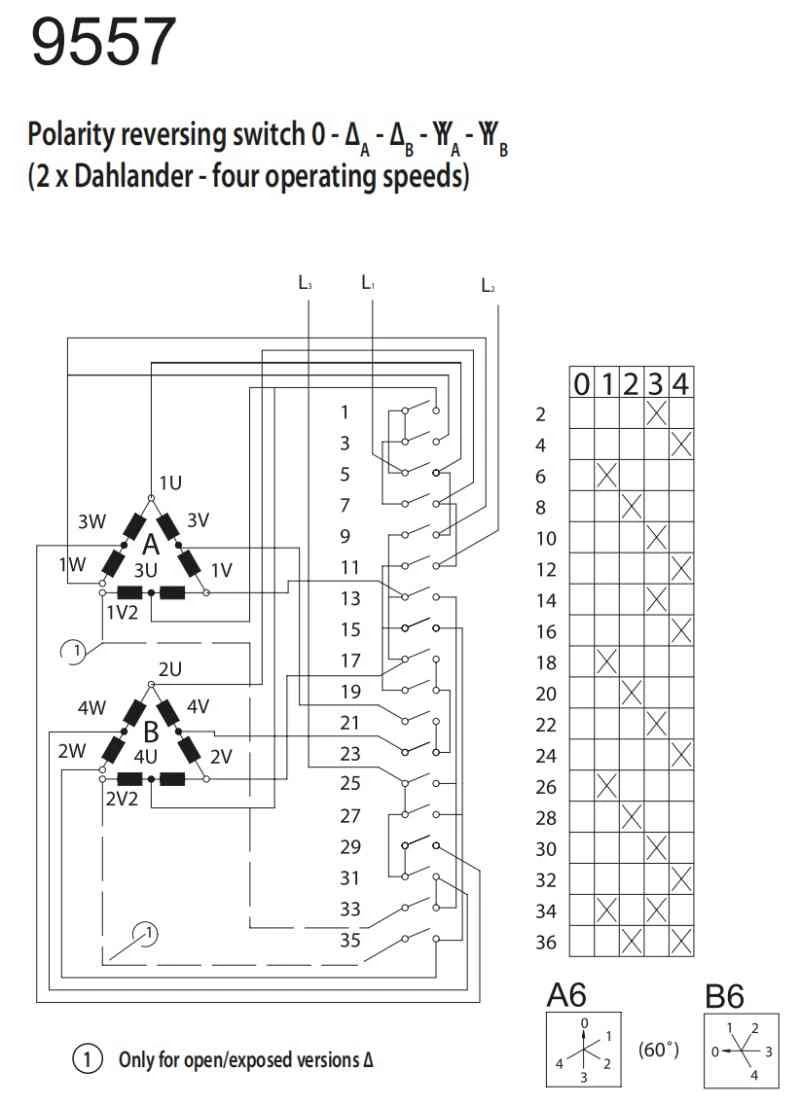

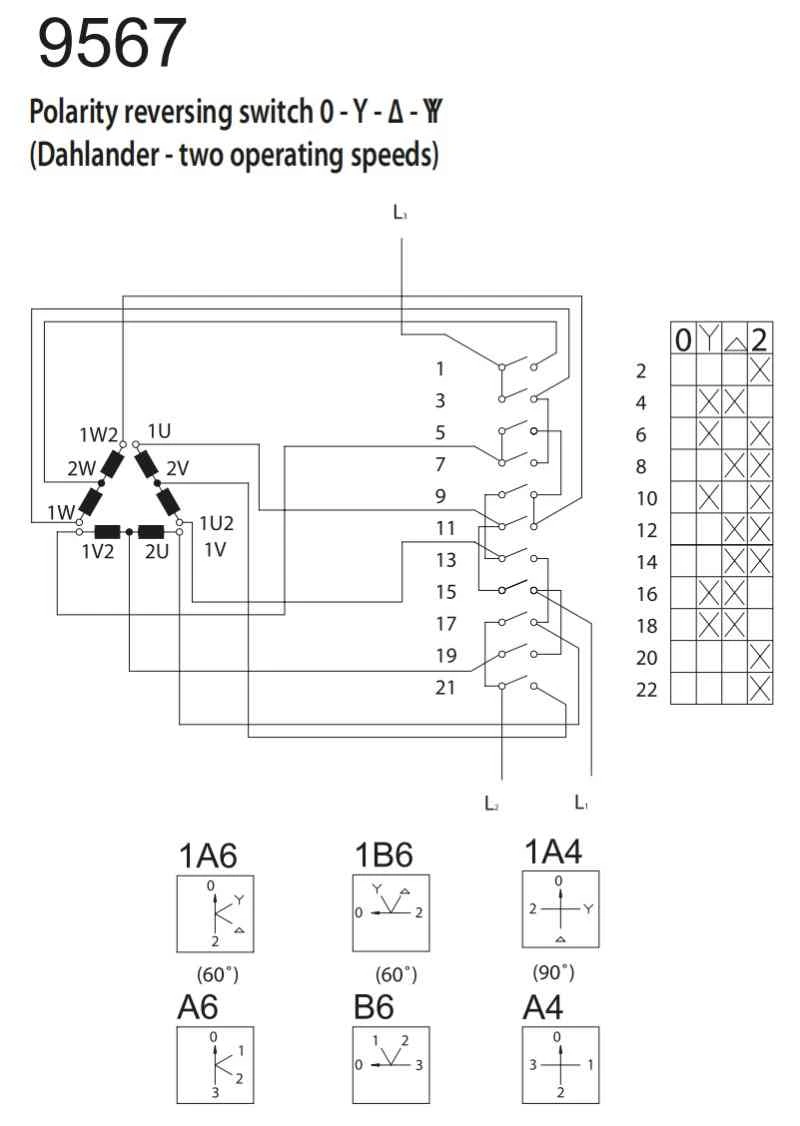

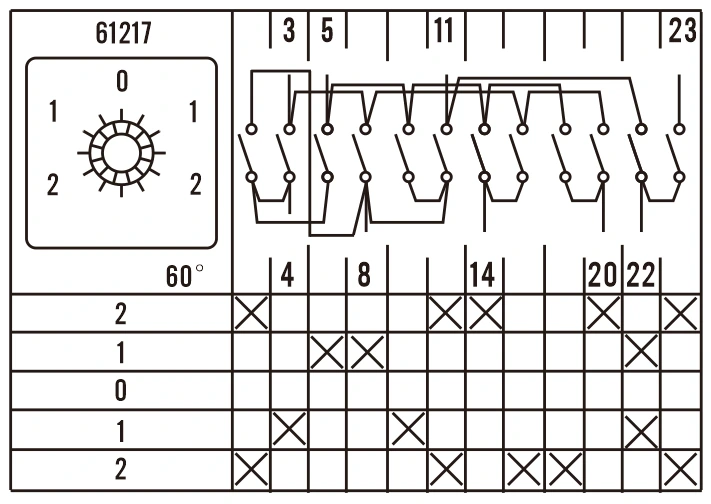

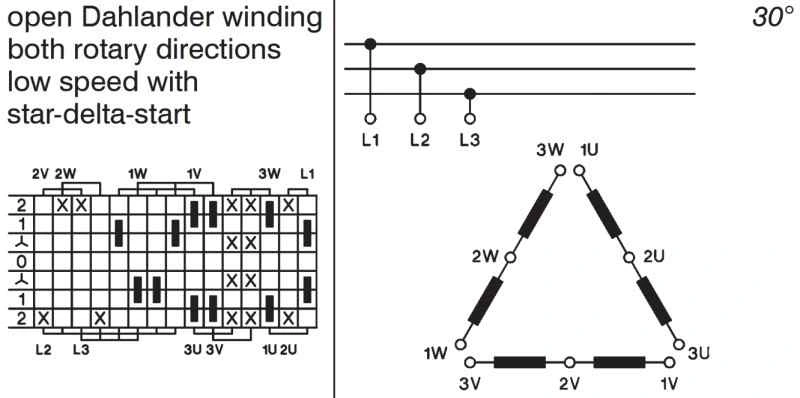

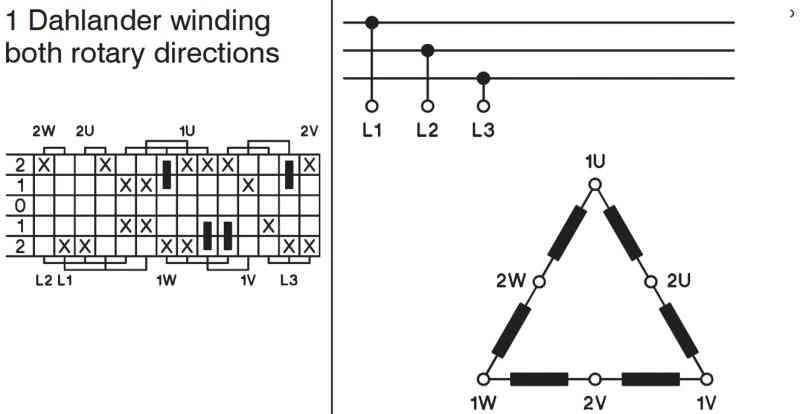

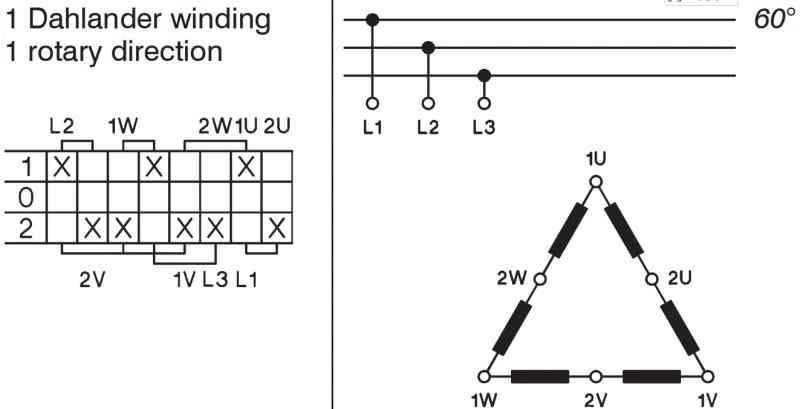

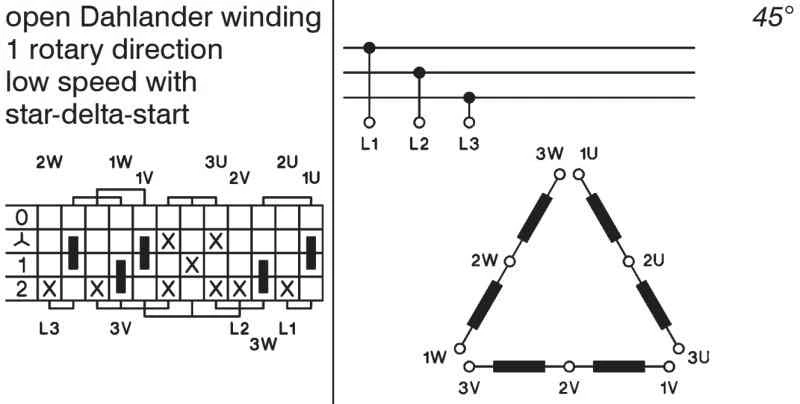

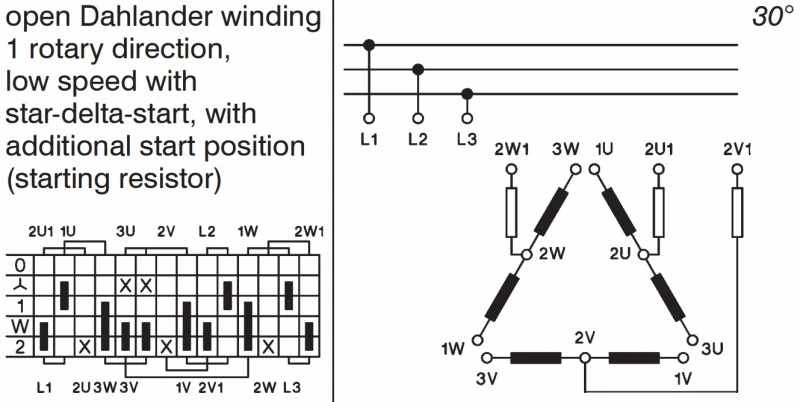

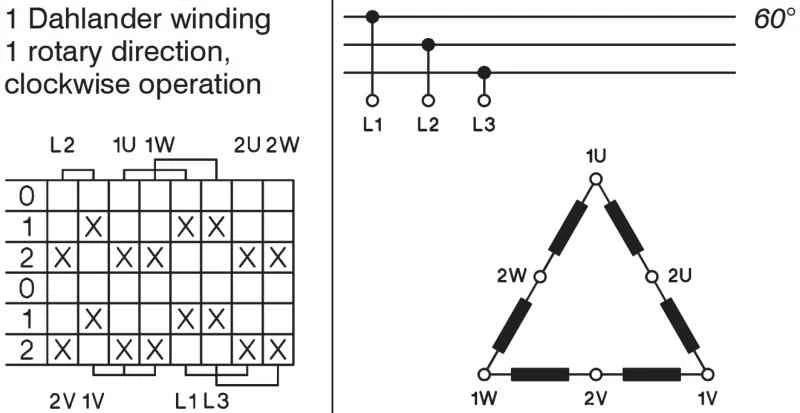

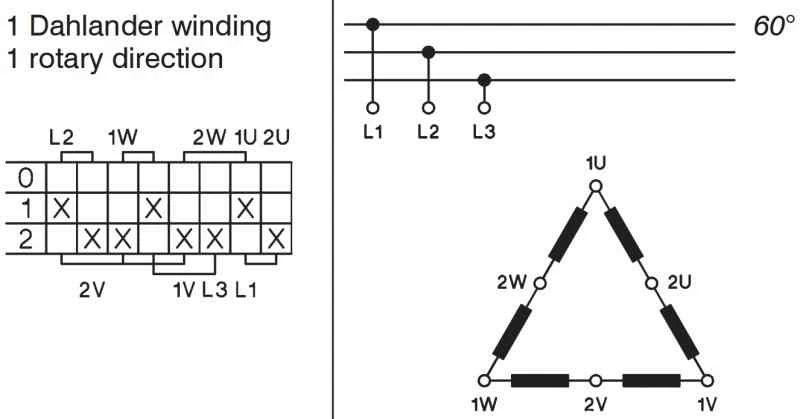

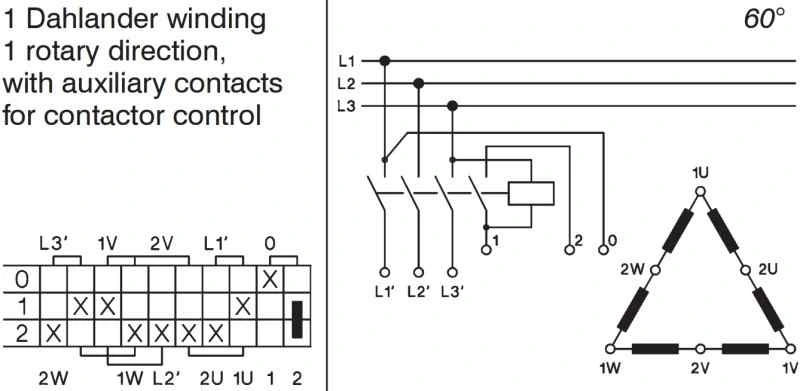

Dahlander switches enable 2-speed operation (e.g., High/Low) by reconfiguring motor windings (typically Δ/YY or Y/YY). They differ from standard switches by handling pole transitions without damaging windings.

▶ Visual Aid (Insert here):

|  |  |

|  |  |

|  |  |

|  |  |

|  |

2. Key Selection Criteria

a) Current Rating & Duty Cycle

- Match the switch’s continuous current rating to the motor’s full-load current (FLC) at both speeds.

- For high-cycling applications (e.g., packaging lines), prioritize AC-3 duty class switches (≥ 100,000 mechanical cycles).

b) Speed Transition Mechanism

- Manual Switches: Cost-effective for infrequent changes (e.g., seasonal HVAC adjustments).

- Motorized/Automatic Switches: Essential for dynamic processes (e.g., CNC machines). Verify transition interlocks to prevent short-circuiting.

c) Safety & Compliance

- Look for IEC 60947-4-1 certification.

- Isolation Function: Ensure the switch provides visible isolation (e.g., rotary cam type) for maintenance safety.

3. Recommended YouTube Resources

Enhance your understanding with these videos:

- “Dahlander Principle Explained“ by The Engineering Mindset

- “Testing a Rotary Dahlander Switch“ by Konrak Switch

- “Common Dahlander Switch Failures & Fixes“ by Electrical Engineering Planet

4. Pro Tips for Integration

- Thermal Protection: Always pair with overload relays rated for both speeds.

- Wiring Check: Use a multimeter to verify contact sequencing before energizing.

- Environmental Factors: For dusty/wet environments (e.g., mills), opt for IP65-rated enclosures.

5. Further Reading

- IEC Standard Overview: IEC 60947-4-1 Document Summary

- Motor Winding Deep Dive: Dahlander Motors

- Switch Maintenance Guide: Konrak Blog: Extending Switch Life

Conclusion

Selecting the right Dahlander switch hinges on current load, transition needs, and safety compliance. Always consult motor datasheets and prioritize certified components. For specialized support in sourcing industrial-grade Dahlander switches, contact Konrak’s technical team.