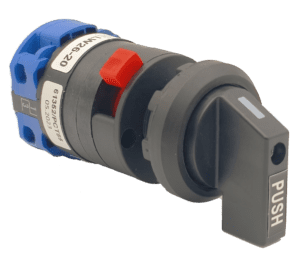

LW26 Rotary Cam Switch with Push To Turn Spring Return Feature: Precision, Safety, and Versatility for Industrial Control

The LW26 Rotary Cam Switch—equipped with a Push To Turn Spring Return mechanism—is a premium industrial control solution engineered to deliver uncompromising safety, seamless operation, and adaptable design for critical applications. Its unique Press to Turn + automatic reset functionality—requiring a deliberate press-and-rotate action followed by a spring-loaded return to neutral—eliminates accidental activation, making it the choice for environments where human error could lead to downtime, injury, or equipment damage. Below, we’ve expanded on how this mechanism integrates with the switch’s core features, enriched real-world use cases, and highlighted why Push To Turn Spring Return is a game-changer for industrial control.

Core Features: How Push To Turn Spring Return Drives Value

The LW26’s design is rooted in industrial-grade reliability and user-centric safety, with the Push To Turn Spring Return mechanism at its heart. Here’s a deeper dive into its key attributes—with a focus on how this feature enhances performance:

1. Push To Turn Spring Return Safety Mechanism: The Gold Standard for Accident Prevention

The defining feature of the LW26 is its Push To Turn Spring Return system, a two-step + automatic reset process that eliminates unintended operation:

- Step 1: Press to Engage: The operator must push the knob inward (a tactile “click” confirms engagement), ensuring deliberate action.

- Step 2: Rotate to Activate: The knob is then turned to the desired position (1–0–2, 0–1, etc.).

- Step 3: Spring Return to Neutral: Upon releasing the knob, a built-in spring automatically resets it to the neutral (off) position—preventing prolonged activation if the operator forgets to reset.

This mechanism is OSHA 1910.147 (Lockout/Tagout) and ISO 13849-1 (Safety-Related Control Systems) compliant, making it ideal for:

- Heavy machinery (e.g., presses, mills) where accidental startup risks injury.

- Marine applications (shipbuilding, offshore platforms) where vibration could trigger误操作.

- Energy systems (power distribution, renewable energy) where circuit selection must be temporary and intentional (e.g., testing a backup generator).

2. Wide Current Range + Push To Turn Spring Return: Versatility for Every Load

The LW26 supports 10A–32A current ratings—paired with Push To Turn Spring Return—to cover everything from light control circuits to heavy-duty power distribution:

- 10A–16A: Suitable for temporary operations (e.g., starting a small pump, activating a conveyor belt) where the spring return ensures the switch resets after use.

- 20A–25A: Ideal for medium-duty equipment (e.g., fans, compressors) where operators need to toggle power temporarily without leaving circuits energized.

- 32A: Designed for critical infrastructure (e.g., backup generators, solar inverters) where intentional, temporary activation is non-negotiable.

Each rating is IEC 60947-3 certified for thermal stability, ensuring consistent performance even under prolonged use.

3. Flexible Mounting + Ergonomic Design: Optimized for Press to Turn Operation

The LW26’s mounting options and ergonomic design are tailored to enhance the Press to Turn experience:

- ø22mm Single Hole: Space-saving design for compact control panels (e.g., IoT edge devices, small machinery) where operators need quick, precise Press to Turn access.

- 36×36mm Four-Hole: Standard industrial mounting for large control cabinets (e.g., factory automation lines) where the 48×48mm escutcheon provides ample space for labeling (e.g., “Emergency Pump – Press to Turn”).

- DIN-Rail Mount: Tool-less installation for modular systems (e.g., switchgear, renewable energy inverters) where Push To Turn Spring Return switches can be easily integrated into existing setups.

The rubberized knob offers a non-slip grip for gloved operators (common in manufacturing, marine, and energy sectors), ensuring reliable Press to Turn action even in harsh conditions.

4. Push To Turn Spring Return vs. Latching: Choosing the Right Mode

The LW26 supports two operation modes—Push To Turn Spring Return (momentary) and latching (fixed)—to suit different use cases:

- Push To Turn Spring Return (Momentary): Ideal for temporary actions (e.g., starting a machine cycle, testing a circuit) where the switch must reset automatically. Example: A worker uses the Press to Turn function to activate a robotic arm, and the spring return resets the knob to off once the cycle is complete—preventing accidental reactivation.

- Latching (Fixed): Suitable for continuous operations (e.g., maintaining power to a lighting system) where the switch remains in the selected position until manually reset.

The 30° rotation angle for Push To Turn operations ensures precise, fatigue-free use for operators, even in high-cycle environments (e.g., assembly lines).

Model Variants: Tailored Push To Turn Spring Return Solutions

The LW26 is available in four variants—each optimized for Press to Turn and Spring Return performance:

Variant 1: ø22mm Single Hole Mount (No Face Plate)

- Key Specs: 10A–16A, Push To Turn Spring Return (1–0–2), IP20 protection.

- Best For: Compact equipment (e.g., IoT sensors, small pumps) where space is limited and temporary activation is critical.

- Why It Works: The minimalistic design reduces panel clutter, while the Push To Turn mechanism ensures operators can’t accidentally leave circuits energized.

Variant 2: 36×36mm Four-Hole Mount (Silver/Black Face Plate)

- Key Specs: 20A–25A, Push To Turn Spring Return (0–1), IP65 optional.

- Best For: Factory automation lines where operators need to toggle power to conveyor belts or fans temporarily.

- Why It Works: The silver/black finish blends with modern panels, and the Push To Turn function prevents downtime from accidental activation.

Variant 3: 36×36mm Four-Hole Mount (Yellow/Red Face Plate)

- Key Specs: 32A, Push To Turn Spring Return (Trip-Neutral-Close), IP65 protection.

- Best For: Safety-critical applications (e.g., emergency stop panels, chemical plants) where high-visibility + automatic reset is non-negotiable.

- Why It Works: Yellow/Red is universally recognized as a “caution” color, and the Push To Turn Spring Return mechanism ensures operators can’t leave emergency circuits energized.

Variant 4: 36×36mm Four-Hole Mount (Padlockable Handle)

- Key Specs: 10A–32A, Push To Turn Spring Return (1–0–2), lockable “OFF” position.

- Best For: Restricted areas (e.g., maintenance zones, nuclear facilities) where unauthorized Press to Turn operation is prohibited.

- Why It Works: The padlockable handle adds an extra layer of security, while the Spring Return mechanism ensures the switch resets even if the lock is removed.

Real-World Applications: Push To Turn Spring Return in Action

The LW26’s Push To Turn Spring Return feature is a staple in:

- Manufacturing: Controlling robotic arms, conveyor belts, and assembly lines—where operators need to start/stop cycles temporarily without leaving equipment energized.

- Marine: Managing power distribution on ships—where vibration could trigger accidental activation, and the Spring Return mechanism prevents long-term energization.

- Renewable Energy: Switching between solar panels, batteries, and the grid in microgrids—where intentional, temporary activation is key to testing and maintenance.

For example, a 32A LW26 with a yellow face plate might be used in a chemical plant to control an emergency pump: the operator uses Press to Turn to activate the pump, and the Spring Return resets the switch to off once the emergency is resolved—preventing the pump from running indefinitely.

Compliance & Reliability: The Push To Turn Spring Return Difference

Every LW26 switch is:

- EN IEC 60947-1/3 Certified: Meets European and international safety standards for Push To Turn and Spring Return functionality.

- CE Marked: Suitable for sale in the EU and EEA.

- RoHS Compliant: Free of hazardous substances (lead, mercury) for eco-friendly operations.

Backed by a 2-year warranty and lifelong technical support, the LW26 is an investment in downtime reduction and operational safety—powered by Push To Turn Spring Return technology.

Final Thoughts: Push To Turn Spring Return Is Non-Negotiable for Modern Industry

The LW26 Rotary Cam Switch with Push To Turn Spring Return feature isn’t just a component—it’s a safety partner that protects workers, equipment, and productivity. Its combination of deliberate operation, automatic reset, and industrial compliance makes it the choice for engineers and facility managers who refuse to compromise on reliability.

Whether you’re building a new production line, upgrading a ship’s electrical system, or maintaining a power grid, the LW26’s Push To Turn Spring Return mechanism delivers the control, safety, and versatility you need to keep operations running smoothly.

Ready to learn more? Contact our team to discuss custom labeling, IP ratings, or volume pricing for your next project. 🛠️