Rotary cam switches are widely used in industrial and electrical applications for controlling motors, circuits, and other electrical systems. Understanding the components of a rotary cam switch is essential for proper installation, maintenance, and troubleshooting.

Main Components of a Rotary Cam Switch

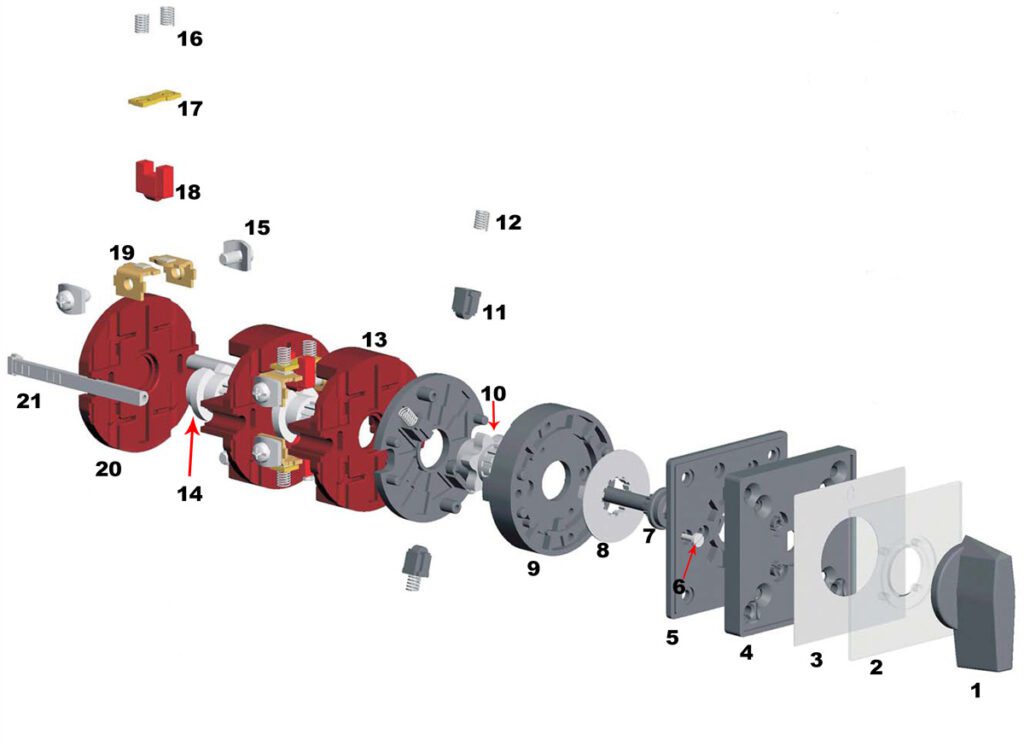

Below is a detailed breakdown of each element:

- Handle/Knob – The user-operated part used to change the switch position.

- Escutcheon plate / Face plate / Indicating Plate / Legend Plate – Decorative or informative plate indicating switch positions.

- Indicating Paper – A label visible through a transparent front plate for position identification.

- Plate Frame – Holds the face plate securely in place.

- Mounting Plate – Used for fixing the switch to a panel or enclosure.

- Holding Screw – Secures the mounting plate to the switch body.

- Shaft/Drive Shaft – Transmits rotational motion to the internal components.

- Limit Cam / Stopper – Limits the rotation to specific positions.

- Latching Mechanism – Keeps the switch in a set position until manually changed.

- Mech Cam – Controls the mechanical movement of the contacts.

- Mech Cam Follower – Follows the Mech Cam to actuate contact changes.

- Mech Cam Follower Spring – Returns the follower to its original position.

- Switching Cell/Chamber – Encloses the contact mechanism.

- Cam / Cam Wheel – Controls the timing and sequence of contact operations.

- Terminal Screw – Connects external wires to the switch.

- Cam Follower Spring – Ensures smooth contact movement.

- Moving Contacts – Open or close the circuit based on the cam position.

- Cam Follower – Follows the cam to actuate contact changes.

- Fixing Contacts – Stationary contact points.

- Bottom Plate – Provides structural support to the switch base.

- Side Rod/Bolt – Offers additional structural support or alignment.

Typical Applications of Rotary Cam Switches

- Motor Control: Used as motor switches for direct-on-line starting, reversing, and star-delta operations.

- Control Circuits: Applied in signaling, control, and measurement systems.

- Industrial Switching: Selector switches, step switches for transformers, welding equipment, resistors, and heaters.

- Automatic Return Switches: For applications requiring automatic reset after operation.

Design Features

- Up to 12 control positions and 12 switching elements (24 contacts) maximum.

- Available with turning angles of 30°, 45°, 60°, and 90°.

- Modular and customizable design for various industrial needs.

Suggested Additions to the Blog

- Illustrated Diagram – A labeled image of a rotary cam switch showing each component.

- Assembly Instructions – Step-by-step guide on how to assemble or disassemble the switch for maintenance.

- Comparison with Other Switch Types – How rotary cam switches differ from toggle switches, push-button switches, and electronic switches.

- Common Faults and Troubleshooting Tips – Guide on identifying and resolving common issues.

- Real-World Use Cases – Examples of how rotary cam switches are used in automation, machinery, and control panels.